Heat exchangers are widely used in petroleum, chemical, light industry, pharmaceutical, energy and other industrial production. However, after long-term operation of the heat exchanger, dirt will form inside, and the accumulation of dirt makes the cross section of the internal passage of the heat exchanger smaller or even blocked, , resulting in insufficient cooling water flow and reduced pressure, leading to downtime and production shutdown; and even causing safety accidents such as blisters, cracks, and tube explosions.

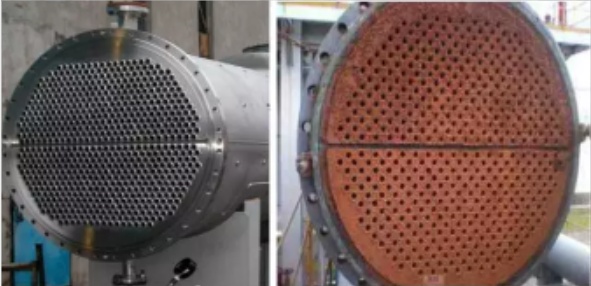

Before and after heat exchanger operation

Chemical cleaning methods for heat exchangers

Chemical cleaning is to generate a certain chemical reaction through the chemical cleaning solution, so that the scale and other deposits on the surface of the heat transfer tube of the heat exchanger are dissolved, shed or peeled off.

During chemical cleaning, there is no need to disassemble the heat exchanger, which simplifies the cleaning process and also reduces the labor of cleaning. The disadvantage is that improper selection of chemical cleaning fluid will cause corrosion and damage to the substrate and cause losses.

Common chemical cleaning agent

● Cleaning agents (including water and organic solvents) that remove dirt by dissolution;

● Surfactant cleaning agents (such as cationic, anionic, nonionic and zwitterionic surfactants) that remove dirt by surface active effect;

● Chemical cleaning agents (such as acid, alkali, salt, oxidant.) that remove dirt by chemical reaction.

Common methods of chemical cleaning

● Circulation method: use the pump to force the cleaning fluid to circulate for cleaning.

● Immersion method: fill the equipment with cleaning solution and set aside it for a certain period of time.

● Surge method: fill the equipment with cleaning liquid, discharge part of the cleaning liquid from the bottom every certain time, and then put the discharged liquid back into the equipment to achieve the purpose of stirring and cleaning.

Chemical cleaning cycle process for heat exchanger

1. Isolate the equipment and drain the water in the heat exchanger well.

2. Clean the pipeline impurities with high-pressure water and close the system.

3. Install a ball valve between the isolation valve and the exchanger, connect which to the delivery pump and conduit, and make the cleaning agent be pumped in from the bottom of the heat exchanger and flow out from the top.

4. Inject the required cleaning agent and repeat the cleaning.

5. Discharge gas at any time and inject appropriate water.

6. Use PH test paper to determine the effectiveness of the cleaning agent.

7. Recover the cleaning solution and rinse it repeatedly with clean water until the pH is neutral.

English

English Español

Español русский

русский