Scholars have studied the shock absorption performance of spherical storage tanks used in the petrochemical industry. The research team added dampers at the bottom of the storage tanks to improve their stability. As for accessories, the dampers can be embedded in the bottom of the storage tanks by means of bolts. The use of the dampers has significantly improved the shock absorption performance of the storage tanks. Scholars have analyzed the insulation structure of large storage tanks and explored the effect of the insulation structure on the shock absorption performance of LNG large storage tanks in advance. The research shows that the insulation layer can improve the shock absorption and reliability of the whole storage tanks to a certain extent. Scholars focus on the seismic performance and thermal insulation performance of large-scale storage tanks and analyze the seismic index of super-large storage tanks and the fluid heat transfer in the tanks by numerical simulation, which provides a theoretical reference for optimizing the seismic performance of super-large storage tanks.

Scholars compare the shaking of different types of large storage tanks in earthquakes and find out the best structure by simulating the damage of different storage tanks in earthquakes. Scholars have studied the anti-periodic vibration performance of large storage tanks, which provides a theoretical basis for the stability design of vertical storage tanks. Scholars analyzed the vibration data of large-scale storage tanks in earthquakes, established the seismic performance grade response library, and completed the interactive system design of tank seismic, which provided a reference for the reliability application of large-scale storage tanks in engineering.

In order to further improve the seismic reliability of large-scale vertical oil storage tanks in China, the seismic performance of large-scale oil storage tanks is studied by numerical simulation method combined with fluid-structure coupling theory, which provides a reference for the seismic optimization design of large-scale oil storage tanks in the future.

1. Mathematical model

When the tank vibrates, the oil and other fluids will shake inside the large storage tank and react with the inner wall of the tank. Moreover, the vibration will cause an eddy current effect in the fluid and fluid-structure coupling reaction, which will deform the tank, and even lead to the failure of the tank in severe cases.

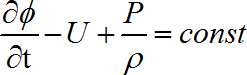

In the dynamic simulation of the large vertical oil storage tank, it is necessary to establish its mathematical model. In this study, fluid dynamics equation, Euler equation, continuity equation and Bernoulli equation should be applied, in which Bernoulli equation is derived as follows:

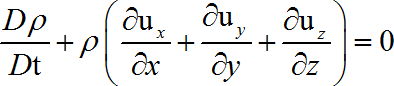

The continuity equation of this study is as follows:

As an advanced fluid mechanics software, Adina software used in this study has great advantages in simulating flow field, fluid-solid coupling field, solid mechanics, temperature field, fluid-acoustic coupling field, etc., and can better calculate the complex fluid-solid coupling and dynamic characteristics of large storage tanks in this study.

2. Design parameters

In order to explore the influence of different storage depths and vibration levels on the performance of large vertical storage tanks, a three-dimensional simplified model of large storage tanks was established in Solidworks according to the actual size of tanks. Because part of the structure of the tank has little influence on the simulation results during numerical simulation, the structure can be partially simplified to reduce the number of grids and improve the calculation efficiency.

In this study, 100,000 cubic meters of large-scale oil vertical storage tank is taken as the research object, and the basic structural parameters of the tank are shown in Table 1. The tank is made of 9 layers of steel plates, with the thickness of the edge plate being 20 mm, the first level wall thickness being 34 mm, and the ninth level wall thickness being 12mm. The radius of the tank is 40 mm, the height of the tank is 21.8 mm, the liquid inside the tank is petroleum, the maximum depth of liquid storage is 20.2 mm, and the temperature under design conditions is 68℃.

3. The establishment of the simulation model

In the numerical simulation of large storage tanks with different storage depths and different vibration levels, it is necessary to establish the simulation model and divide the grid. In this study, five different depths of liquid storage are selected, which are 40%, 50%, 60%, 70% and 80% of the maximum depth of liquid storage respectively. Therefore, it is necessary to establish simulation models of tanks with five different depths of liquid storage before numerical simulation. Three-dimensional simplified models of five kinds of storage tanks are imported into CFD software for grid division. The liquid storage is set as fluid domain, different grid sizes are adopted in different parts of the tank, hexahedron grid of 50 mm is adopted in the fluid domain, tetrahedron grid of 45 mm is adopted in the surface of the tank, and tetrahedron grid of 5 mm is adopted in the complex structure inside the tank. After completing the grid division, it is necessary to check whether the grid quality meets the requirements of the simulation software in CFD software. The grid quality of the five models divided in this study is above 0.32, which can meet the accuracy requirements of simulation.

After completing the grid division, the grid models of five kinds of large vertical storage tanks are respectively imported into Adina software for numerical simulation. The boundary conditions of simulation are set in Adina software, and different vibration grade parameters are input. Four kinds of vibration grade parameters are set, which are 5.5 degrees, 6.5 degrees, 7.5 degrees and 8.5 degrees respectively. Input the relevant parameters in Table 1 and Table 2 into the simulation software, select the incompressible fluid, which is a non-viscous and non-heat transfer unit, and carry out numerical simulation after setting the relevant parameters.

4. Analysis of numerical simulation results

In order to better compare the effects of different liquid depths and different earthquake grades on the performance of oil storage tanks, vertical stress and reliability index are introduced in this study. The greater the vertical stress, the more serious the tank deformation is. The lower the reliability index, the more likely the tank will fail.

By analyzing the vertical stress data of the tank under five working conditions, it is found that with the increase of liquid depth in the tank, the vertical stress of the large storage tank increases, the deformation of the tank becomes more serious, and the tank is more likely to fail. Under design conditions (the vibration level is 7.5 degrees), the vertical stress of large storage tanks with different storage depths shows that with the increase of storage depth, the deformation of the external area of the tank increases obviously.

It can be seen from the vertical stress trends of large storage tanks with different storage depths and earthquake grades that the higher the depth of liquid inside the tank, the greater the vertical stress of large storage tanks and the lower the reliability index. When the depth of the reservoir is small, the influence of earthquake grade on radial force is small. When the depth of liquid in the tank reaches 60%, the influence of earthquake grade on the radial force will be significantly improved, which will easily lead to an over-limit of reliability index and failure of the tank. When the depth of liquid inside the tank is the same, the higher the earthquake level, the greater the vertical stress of large vertical oil storage tanks, and the lower the reliability index.

When the depth of liquid storage is 60%, the vertical stress of large storage tanks with different earthquake grades shows that the vertical stress increases significantly with the increase of earthquake grade, which is consistent with the above-mentioned trend.

5. Conclusion

In order to explore the seismic reliability of large-scale oil storage tanks, the seismic performance of large-scale oil storage tanks was numerically simulated by Adina software combined with fluid-structure coupling theory, and the vertical stress and reliability indexes were introduced to explore the effects of different liquid depths and different seismic grades on the performance of oil storage tanks, which provided a reference for future research on seismic reliability of large-scale oil storage tanks. The main conclusions of this study are as follows:

(1) Liquid depth and seismic grade have a significant influence on the reliability of large vertical oil storage tanks.

(2) When the earthquake level is the same, the higher the depth of liquid inside the tank, the greater the vertical stress of the large storage tank.

(3) When the depth of liquid storage is small, the influence of earthquake grade on radial force is small. When the depth of liquid in the tank reaches 60%, the influence of earthquake grade on radial force is significantly improved, which makes the reliability index exceed the limit and the tank fails.

(4) When the depth of liquid inside the tank is constant, the higher the earthquake grade, the greater the vertical stress of the large vertical oil storage tank, and the lower the reliability index.

(5) In order to ensure the reliability of large oil storage tanks, the depth of liquid inside the tanks should be less than 60% in design.

English

English Español

Español русский

русский