Multi-media filters are commonly used in water treatment. They're great at removing things like suspended solids, colloids, and oils from water. These filters use different layers of media, each with its own filtering properties. But, to make sure the filter runs smoothly and efficiently, there are a few key things you need to focus on. Proper operation and regular maintenance are crucial to keep the filter working well and extend its life.

Choosing and Designing the Media

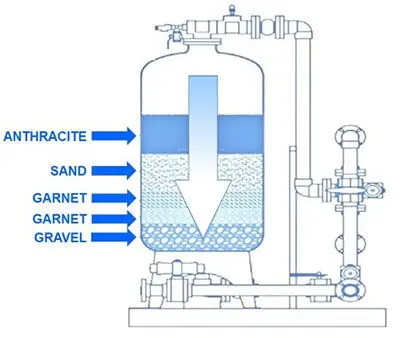

The choice of filter media is really important for the filter's performance. Some of the most common types of media are quartz sand, natural sea sand, and anthracite coal. When picking the right media, make sure to keep these things in mind.

1. Carbon Content in Anthracite Coal

The more carbon the anthracite coal has, the better it can absorb contaminants and filter out impurities. The carbon content in anthracite coal usually ranges from 30% to 90%. More carbon means better filtering, but it also costs more.

2. Media Grain Size Design

Each layer of media should have a different grain size and function. For example, the bottom layer typically uses larger quartz sand (about 24mm), while the top layer uses finer sand (0.5–1.0mm). Anthracite coal with a grain size between 1–2mm can be added where needed. A well-thought-out grain size design helps the filter do its job efficiently by balancing fine filtration at the bottom with coarse filtration at the top.

The Importance of Backwashing

Backwashing is a key part of filter maintenance. It helps clear out the contaminants that build up in the media layers, restoring the filter's performance. Here's what to consider when backwashing.

1. Controlling the Backwash Intensity

If the backwash isn't strong enough, the media won't loosen properly, and the contaminants won't be fully removed. On the other hand, if the backwash is too strong, you could wash out the smaller particles of media, damaging the filter structure. Getting the backwash intensity right is key to keeping the filter running smoothly.

2. Backwash Time and Frequency

The time and frequency for backwashing should be adjusted based on how the system is being used. Typically, backwashing is set to occur every 8 hours, but it depends on things like the water quality and how clogged the media is. Too much backwashing wastes energy, while too little can affect the filter's performance.

3. Combining Backwash and Air Washing

Since multi-media filters use several layers of media, just water backwashing might not fully clean everything. Air washing helps loosen deeper deposits in the media, while water washing clears surface dirt. Using both methods together makes cleaning more effective.

Regenerating and Cleaning the Media

Regularly regenerating and cleaning the media is crucial for keeping the filter working long-term. Over time, contaminants build up in the media, increasing pressure and reducing flow. If you don't clean it in time, the filter bed can become compacted or even form holes, causing the filter to stop working properly. That's why regenerating and cleaning the media is an essential part of maintenance.

1. Automatic Backwash System

Many modern filters come with an automatic backwash system. This system starts backwashing based on set pressure differences and time intervals. Setting the right pressure difference (usually around 0.8 kg) and backwash time helps maintain the filter's efficiency.

2. Manual Cleaning When Needed

Even though automatic backwashing handles most of the regeneration, sometimes manual cleaning is still necessary. If backwashing doesn't fully clean the media, you may need to do a manual cleaning to make sure the media layer is loosened up and fully cleaned.

Operational Guidelines and System Management

To keep the filter running smoothly, operators need to use and manage the system correctly. Incorrect operation can cause instability and affect water treatment. Here are some important guidelines to follow.

1. Controlling Inlet Pressure

High inlet pressure can reduce the space between the media particles and increase their roughness. This can mess with how the particles line up and affect the filter's efficiency, or even cause sand leakage. Keep the inlet pressure within a reasonable range to avoid these issues.

2. Media Layer Height and Stability

While a taller media layer can improve filtration, it also increases pressure, which can affect how efficiently water flows through the filter bed. The height of the media layer needs to be carefully designed to balance good water treatment with acceptable operating pressure.

3. How Often the Filter Runs

If the filter operates too frequently or too rarely, it can affect stability. Running the filter too often can wear out the media faster, while running it too little might mean it's not cleaned well enough, hurting filtration performance. Adjust the operation frequency based on the water quality and system load.

Common Issues and How to Fix Them

During operation, multi-media filters can face common problems, like sand in the effluent, uneven media grain sizes, or improper operation. Here are some solutions.

1. Sand in the Effluent

If the media particles are rough or uneven, or if the grain size is off, the particles may break loose during filtration. The best solution is to choose the right grain size for the media and maintain a moderate backwash intensity.

2. Increased Pressure Loss in the Media

As contaminants accumulate, pressure loss can increase, reducing flow and possibly causing poor water quality. Regular backwashing and cleaning can help minimize this problem and keep the media stable over time.

Conclusion

Multi-media filters are effective at removing suspended solids and other contaminants from water. However, to make sure they operate smoothly and deliver the best filtration performance, it's important to follow the right operating procedures, carefully choose and arrange the media, and perform regular backwashing and regeneration. With proper management and maintenance, multi-media filters can consistently provide great performance in water treatment.

English

English Español

Español русский

русский