Vertical pressure vessel and vertical installed equipment

All kinds of containers in chemical plants are fixed at a certain position in the production process through the support. We call a vertically installed, round-shaped container a vertical container. Common vertical containers include vertical vessels, reactors, vertical tanks, etc.

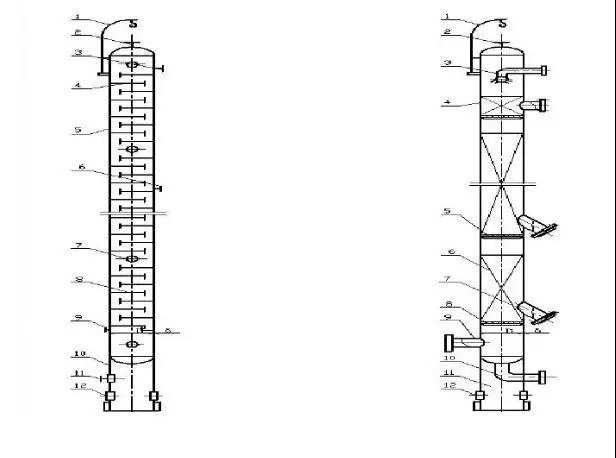

The vertical vessel is one kind of vertical equipment and one of the most important equipment in chemical and oil refining production. It enables close contact between the gas and liquid or liquid-liquid phases to achieve the purpose of mass and heat transfer. The main characteristics of the vertical vessel are: high size, large aspect ratio, and heavy load. In addition to the pressure load and temperature load, the tower body also bears wind load, seismic load and weight load. The support of the vertical vessel is usually a skirt support. The entire weight of the vessel is supported by the skirt, and the anchor bolts fix the skirt on the foundation.

Vertical vessel classification

1. According to the operating pressure, there are pressurizing tower, atmospheric tower and vacuum tower;

2. According to unit operation, there are rectifying tower, absorption tower, desorption tower, quenching tower, reaction tower, drying tower, etc.;

3. According to the internal structure, there are plate tower and packed tower.

Main components and functions

Whether it is a plate tower or a packed tower, in addition to various internal parts, it is composed of tower body, support, manhole or hand hole, demister, adapter tube, hanging column and escalator, operating platform, etc.

1. Tower body. The tower body is the shell of the tower equipment. The common tower body consists of cylinders of equal diameter and thickness and upper and lower heads. The tower equipment is usually installed outdoors, so in addition to tower body's withstanding a certain operating pressure (internal or external pressure) and temperature, the wind loads, seismic loads, and eccentric loads of the tower body must be also considered. In addition, it must meet the strength, stiffness and stability requirements during pressure test, transportation and lifting.

2. Support. Tower support is the connection structure between tower and foundation. Because the tower equipment is tall and heavy, in order to ensure its sufficient strength and rigidity, skirt-type support is usually used.

3. Manholes and hand holes. For installation, maintenance, inspection, etc., manholes or hand holes are often provided on the tower body. Different tower equipment has different requirements for the structure and location of manholes or hand holes.

4. Adapter tube. Used to connect process pipelines and connect tower equipment with other related equipment. According to its use, it can be divided into liquid inlet pipe, liquid outlet pipe, return pipe, air inlet and outlet pipe, side line extraction pipe, sampling pipe, instrument adapter tube, adapter tube for liquidometer, etc.

5. Demister. Used to trap liquid droplets entrained in the airflow. The performance of the demister has a great influence on the removal efficiency and separation effect.

6. Hanging column. Installed on the top of the tower, mainly used for lifting and transporting the tower internals during installation and maintenance.

English

English Español

Español русский

русский