Accumulators are very useful in fluid power systems. It is used to store energy and eliminate pulse. They can be used in the hydraulic system to reduce the specification of the fluid pump by supplementing the fluid of the pump. This is done by storing the energy in the pump during the low-demand stage. They can be used as buffers and absorbers of fluctuations and pulses. They can cushion the pounding and reduce the vibration caused by the sudden start or stop of the power cylinder in the hydraulic circuit. When the liquid is affected by the temperature rise and fall, the accumulator can be used in the hydraulic system to stabilize the pressure change. They can distribute pressurized fluids, such as grease and lubricating oil.

At present, the most commonly used accumulator is the pneumatic-hydraulic type. The action of gas is similar to that of a buffer spring, and it works together with fluid, separated by a gas piston, a thin diaphragm or an airbag.

The Working Principle of the Accumulator

Under the action of liquid pressure, the volume change (at the same temperature) is minimal, so if there is no power source (that is, the supplement of high-pressure liquid), the pressure of the liquid will decrease rapidly.

However, the elasticity of gas is much greater, because gas is compressible. It is still possible for gas to maintain a relatively high pressure even with a large volume change. Therefore, when the accumulator is replenishing the hydraulic oil of the hydraulic system, when the volume of the liquid has changed, the high-pressure gas can continue to maintain the pressure of the hydraulic oil, so that the volume of the hydraulic oil in the container becomes smaller due to the replenishment of the hydraulic oil, which will lead to the rapid pressure loss of the hydraulic oil.

As for nitrogen, the main reason is that nitrogen is stable in nature and does not have oxidation or reduction performance, which is very beneficial to the maintenance of hydraulic oil performance and will not cause oxidation or reduction denaturation of hydraulic oil.

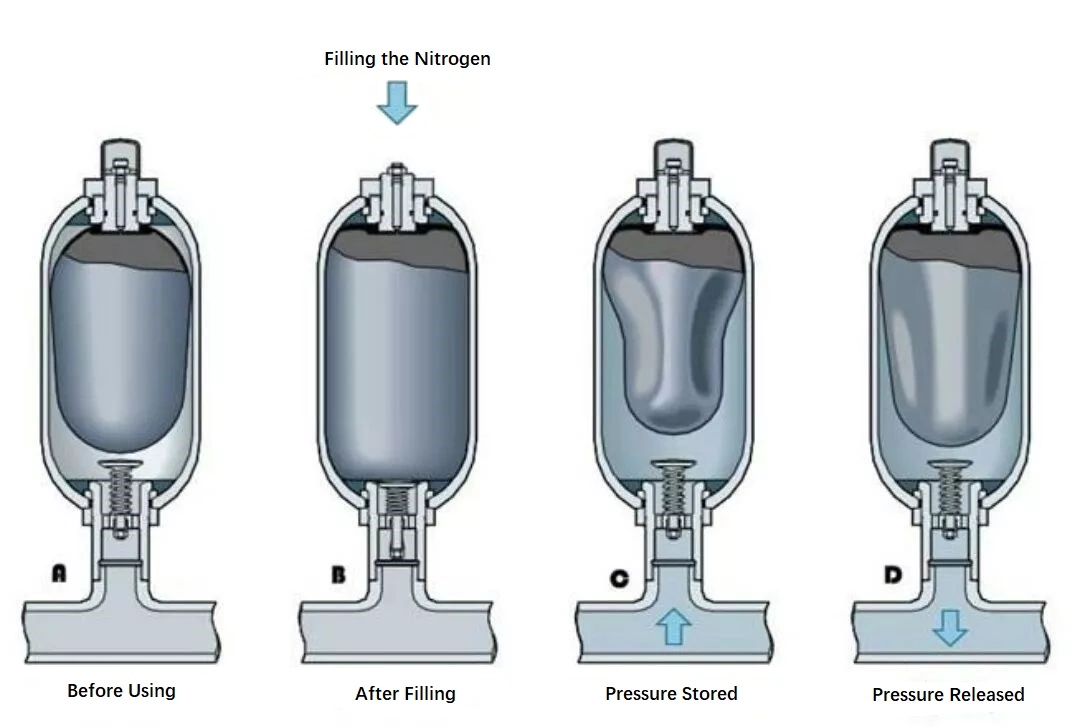

Nitrogen is the pre-charging pressure, which is installed in the airbag of the accumulator and separated from the hydraulic oil. When you fill the accumulator with hydraulic oil, due to the pressure effect of the nitrogen airbag on the hydraulic oil, that is, the pressure of the hydraulic oil is equal to the nitrogen pressure. As the hydraulic oil rushes in, the nitrogen airbag is compressed, and the nitrogen pressure increases and the pressure of the hydraulic oil increase with it until the hydraulic oil reaches the set pressure.

The function of the accumulator is to provide hydraulic oil with a certain pressure, which is produced by the action of nitrogen.

The Main Function of the Accumulator

1. As an auxiliary power supply

The actuators of some hydraulic systems act intermittently, and the total working time is very short. Although the actuators of some hydraulic systems do not act intermittently, their speeds vary greatly within a working cycle (or a stroke). After the accumulator is installed in this system, a low-power pump can be used to reduce the power of the main drive, making the whole hydraulic system small in size, light in weight and cheap in price.

2. As an emergency power source

For some systems, it is required that when the pump fails or the power is cut off (the oil supply to the actuator is suddenly interrupted), the actuator should continue to complete the necessary actions. For example, for safety reasons, the piston rod of the hydraulic cylinder must be retracted into the cylinder. In this situation, an accumulator with an appropriate capacity is needed as an emergency power source.

3. Supplement leakage and keep constant pressure

For the system where the actuator does not act for a long time, but the pressure should be kept constant, the accumulator can be used to compensate for the leakage so that the pressure can be kept constant.

4. Absorb hydraulic impact

As a result of sudden reversing of reversing valves, a sudden stop of hydraulic pump, a sudden stop of movement of actuating element, and even artificial emergency braking of actuating element, the liquid flow in the pipeline will change dramatically, resulting in impact pressure (oil impact). Although the safety valve is installed in the system, it is inevitable to produce short-term pressure surges and impacts. This kind of impact pressure often causes the instruments, components and sealing devices in the system to break down, even damage or pipeline rupture. In addition, it will cause obvious vibration of the system. If an accumulator is installed before the impact source of the control valve or hydraulic cylinder, this impact can be absorbed and mitigated.

5. Absorb pulsation and reduce noise

The pulsating flow of the pump will cause pressure pulsation, which will make the movement speed of the actuator uneven, resulting in vibration, noise and so on. Connecting an accumulator with a sensitive response and small inertia in parallel at the pump's outlet can absorb the pulsation of flow and pressure and reduce noise.

English

English Español

Español русский

русский